Pre-press and offset printing: cutting coating blankets and rubber varnish plates by means of a flatbed cutting machine

In this article we talk about the pre-press and offset printing: we analyse the processes of the cutting of coating blankets and rubber varnish plates using a flatbed cutting machine, such as the Valiani ones.

The phases of printing

The complex world of printing is composed of pre-press and post-press phase. While the post-press stage involves lots of finishing devices, including the cutting and creasing phase, the pre-press is a fundamental part of the graphic printing process, with a strong focus on the offset printing.

Offset printing is a traditional and still widely used printing method that involves the transfer of ink from a metal plate to a rubber blanket and then onto the printing surface, typically paper.

Off-set printing

Composed of rubber or rubber-like material, the offset blanket receives the inked image from the printing plate and transfers it with precision onto the paper. The ink must be taken quickly off the plate and applied just as quickly onto the surface of the substrate.

This indirect method ensures that the printing surface remains free of direct contact with the inked plate, contributing to the consistent and high-quality reproduction of text and images.

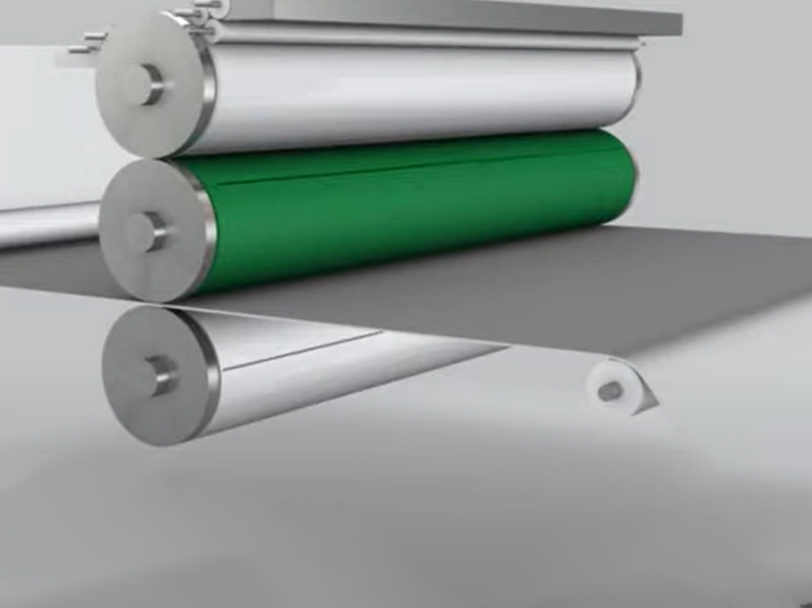

Offset printing is based on a mechanism consisting of three cylinders, including a plate cylinder (matrix), a blanket cylinder a pressure one.

The second cylinder is coated with a caoutchouc rubber, which receives the ink from the plate cylinder and impresses it on the printing substrate (paper or cardboard) thanks to the pressure exerted by the third cylinder, called the pressure cylinder.

Press blankets creation

Printing press blankets are generally showcasing five main advantages, from precision to top-notch print quality, from longevity to waste reduction to strongest match and adaptability to plenty of jobs.

But they require to be perfectly cut. The offset market offers a complete line of strippable coating plates for in line coating.

The most popular ones range between 1,15 mm and 1,35 mm and both polyurethane/polyester and rubber surface coating plates are available to meet all printers’ requirements for coating.

The film can be bonded to an aluminium plate or to polyester foil as required. The transparent film makes it easy to trace the relevant shape for the cut-outs, i.e. when placed on a copy of an offset plate, the shapes will clearly visible.

But you need a cutting table with a half-cut tool for that (such as the Valiani machines). The customer makes a file to leave the top layer of the coating plate only where the varnish has to be printed.

Different types of half cuts: 40° bevel vs 90° straight cut

When it comes to cutting, companies like Valiani offer a twofold solution: a 90° straight cut or a 40° bevel cut, which is more adequate for intricate curves and shapes, also resulting in a longer life of the adhesive glue. Having at disposal both sounds fruitful! Be the plates rubberized on polyester-made, these tools are necessary to get a smooth finishing and stripping process at the very end.

Flatbed cutting machine for varnish plates

It is becoming more and more common to use any flatbed machine for cutting samples for cutting varnish blankets. This process used to be a manual one, but now a lot of offset printing presses have been appreciating first-hand the benefits of digital cutting when it comes to rubber blankets.

But why an offset printing press might need a flatbed cutting plotter for varnish plates?

Digital cutting first of all reduces the blankets preparation time, with translates into no more outsourcing and reduced downtime. Do in in-house means in turn better overall control over the quality of the plates. If the plates is well cut, then can be reused more than once. Beyond the intrinsic reasons for the cutting itself, another aspect can be accounted for the fact that cutting tables are generally very compact with a small footprint. No extra space is needed and also no further operator too, as the same person can run the cutting machine and the printing one.

Flatbed cutting machines like Valiani products also help get a more precise cut. The plotter cuts faster and accurately on any and complicated shapes too (designs, circles and half circles which hard to cut manually).

Personalized packaging and samples

Cutting tables are often positioned in the prepress stage. This makes it possible to create in-house packaging and mock ups. Thus, the printing presses can further amortise a company’s investment of the machinery. These boxes can be printed or not.

In the first scenario, a camera recognises the crop. In the second, the cardboard or paper are neutral where 100% precision is achieved by means of the zero point. This is the intersection of the x and y axis. In this way the operator can make no mistake in placing the plate onto the cutting table.

Creating custom packaging and high-end box mock-ups is consistent with the offset printing market. Many times, printing companies need to design well-made packaging before sending it for large-volume production. A small and compact flatbed cutting machine allows for all of the jobs revolving around the creation of a packaging box.

From cutting to creasing on a neutral cardboard and half-cutting the coating blanket to be applied on the offset press.

Custom Corrugated Packaging

In the offset-printing market, custom corrugated packaging plays a major role. Not only does it protect the products, but also reflects the essence of the brand. These features can be used as part of the company’s marketing of its product.

Offset printing often specialises in the design in food, cosmetics, perfume, chemical and pharmaceutical packaging. The packaging design must take into account the functionality and protection of the product. While at the same time, highlighting the product, the brand and the message to be conveyed. Companies study, conceive and design customised packs capable of being both functional and stylish. This creates a positive, purchasing experience for the customer.

A tailor-made packaging service can boost the perception and lure of products.

Stripping phase

If the packaging is very well done, this is also due to the quality of the cutting of the varnish plate. The very last part of a well-made blanket cutting is the stripping part. The polymer needs to be clean cut and stripped easily and without residues. After proper half-cutting on the blanket, the operator is required to precisely peel off the top layer of the plate by means of a stripping tool.

In the intricate journey of the ink, from plates to paper, passing through the coating blanket, printing varnish plates ensure harmony and precision. Their role in achieving high-quality prints cannot be overstated, and the benefits they bring to the printing process are multifaceted.

From precision and consistency to reduced waste and extended equipment lifespan, these blankets are an indispensable part of the modern printing industry, silently contributing to the visual allure of the printed page.

Correctly cutting and stripping the cut plate is therefore an essential key to make the printing process go smooth, safeguarding quality, colours transfer and overall prestigious image of the final packaging.

What is Valiani’s proposal in this field of cutting coating blankets and rubber varnish plates?

Invicta

Extremely versatile, precise and intuitive, it is the first choice for those looking for a high quality cutting machine with a low investment.

OPTIMA

A digital cutting machine, designed for the printing and packaging industry with the aim to manage complex die cutting processes. It is available in different sizes, with a wide range of tools and accessories

Integra

All-in-one machine designed for the printed signage and packaging industry with the aim to manage complex die-cutting processes.

The ideal tool for a perfect rubber cut

Maximize your performance with our pneumatically operated oscillating head, ideal for making complex cuts and shapes on a wide range of materials.

Which other costs can I expect to face over time?

As already mentioned, Valiani with his Invicta is able to guarantee a high quality cut for a very low initial investment. In addition to this, Valiani can ensure negligible operating and maintenance costs, and this is confirmed by the chance of extending the warranty to a full 5 years. All this at no additional cost.

Benefits of a cutting machine

to cut rubber blankets

and varnish plates in house:

- Reducing the blankets preparation time

- No more outsourcing to third parties

- Reducing downtime

- Better overall control over the quality of the plates

- Proved quality and re-usability of the plate

- Small footprint (no extra space is needed)

- No further operator is needed (can run both the cutting machine and the printer)

- Creating box samples/prototypes/mockups and short runs (both printed and neutral templates)

- Higher speed and accuracy also on complicated shapes too (designs, circles and half circles hard to cut manually)

- Determination of the origin of the cut in an absolute way (thanks to the so-called zero point which is the intersection X and Y axis)