ICO adopts Optima 160 to support packaging design and POP materials

Discover how Optima 160 supported the packaging design and POP materials for ICO, a company that produces corrugated cardboard, packaging, and paperboard materials. Andrea Tempesta, ICO Lab’s Designer, shares the story on the pages of Italia Publishers.

The Italian corrugated group invests in the Valiani Optima 160 cutting system to support its team’s design and prototyping processes

Between 2018 and 2019, an ambitious investment plan of 20 million euros brings the following assets to ICO: an Agnati Quantum2 corrugator, a new vertical warehouse, and the single-pass inkjet printing machine HP PageWide C500. These innovations equip the company with state-of-the-art resources for producing corrugated cardboard packaging. With three plants located between Abruzzo and Puglia, the company manufactures corrugated cardboard, as well as numerous types of packaging and paperboard materials.

Founded in Pescara in 1952 by Loreto Lancia, ICO is now led by the second generation of the family, which is overseeing the entry of the third generation through a process of managerialization, deemed necessary due to the company’s increased size.

In addition to investing in cutting-edge printing and converting technologies, over the last decade, the company has allocated significant resources to further enhancing and meticulously controlling the quality. They have also focused on creating product lines that can leverage the increased production capacity and customization possibilities offered by digital technologies. In line with this approach, ICO has integrated a group of packaging designers into its workforce and established ICO Lab, an innovation and design department recently reinforced with the opening of a design office in Rome.

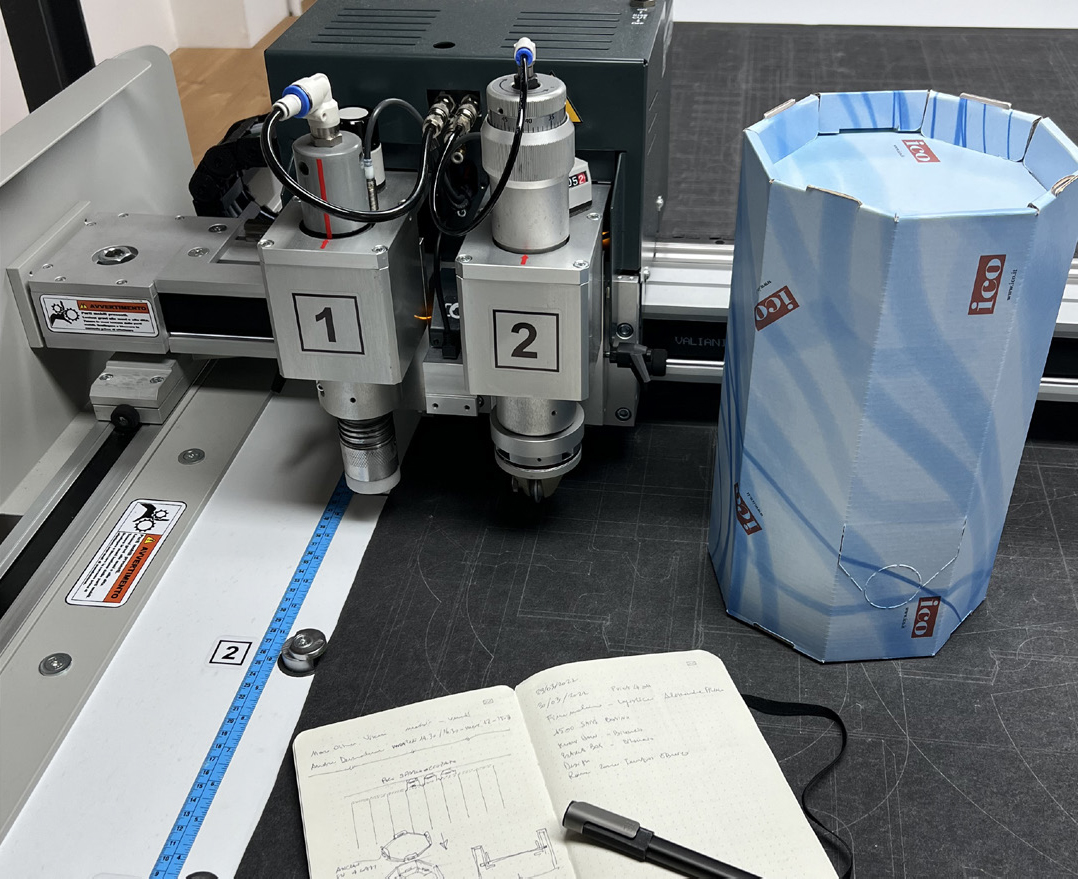

In late 2022, ICO inaugurated a space dedicated to the design and prototyping of innovative and eco-sustainable POP materials in the capital city. Here, ICO has installed a multifunctional digital cutting system, the Valiani Optima 160.

A “lab” to interpret market changes

ICO produces packaging and displays for a diverse and demanding clientele, including food and cosmetic industries, wineries, fruit and vegetable producers and wholesalers, retailers, and large-scale retail chains. With the introduction of single-pass water-based inkjet printing, complementing its existing flexo lines, the company has expanded its range of customized primary and secondary packaging. The need to create complex products in shorter timelines prompted ICO to invest in cutting-edge technologies, expertise, and collaborators with a “digital” mindset.

Among them is Andrea Tempesta, a designer specializing in cardboard displays and POP materials, who joined ICO in 2022 to support the technical and sales team. The ICO Lab’s activity begins with an analysis of functional and aesthetic requirements, which are then translated into graphic and structural designs.

Andrea Tempesta

ICO Lab Designer

“Accustomed to using renowned, highly productive, and expensive cutting-edge technologies, I was struck by discovering such an effective and well-built machine.”

The digital cutting technology supports research, development, and design efforts.

ICO Lab carries out prototyping, testing, and validation activities for new packaging and displays, utilizing suitable hardware and software platforms.

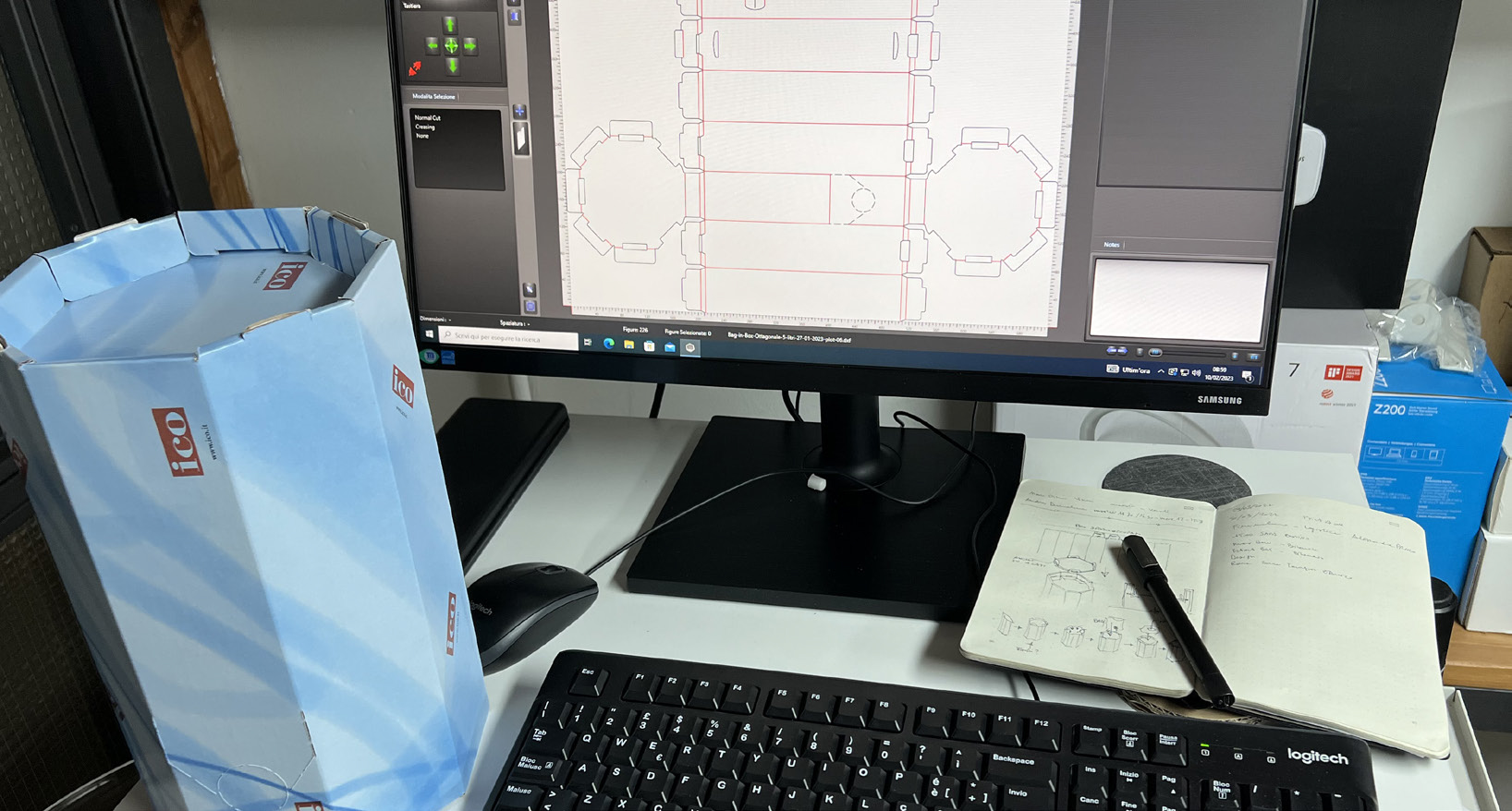

“The creation of ICO Lab by the company stems from the desire to satisfy customers by expanding the possibilities to experiment with solutions that meet their demands for functional and visual innovation,” explains Andrea Tempesta, Designer at ICO Lab. “I like getting my hands dirty, in pure Art Attack style. If I have an idea, I draw it on my digital sketchbook, then digitize it with design software, and create a scaled mockup.”

In addition to corrugated cardboard, when necessary, the ICO Lab team also tests alternative materials, evaluating their use in projects. The ability to internally produce samples and prototypes of boxes and displays is of great importance for the company. To streamline processes, ICO decides to introduce a compact digital cutting system in its Rome design office as well.

Why Optima 160

ICO Lab identified the Valiani Optima as the ideal cutting platform to meet its production needs, and the Optima 160 model as the most suitable “fit” for the available space. With a cutting area of 1,230×1,630 mm, a vacuum table, and a two-position multi-tool head, the machine can simultaneously execute through-cutting and creasing of stretched cardboard, corrugated and fibrous cardboard, honeycomb cardboard, Forex, and other materials.

By changing the tool, the machine can perform V-angle cuts, half-cutting of adhesive materials, and pen marking. Thanks to the camera installed on the cutting head, the system recognizes registration marks on printed files.

To test its effectiveness before the purchase, the ICO team visits the Valiani demo center, subjecting the Optima 160 to intensive processing cycles on various types of cardboard, using the most complex files.

“Accustomed to using well-known, highly productive, and expensive cutting technologies, I was impressed to discover a machine that is so effective and well-built, with a favorable quality-to-price ratio,” says Tempesta. “Visiting Valiani, I was fascinated by their organizational structure and construction practices. From lathe operations to assembly on lean production, Valiani creates the product from start to finish with meticulous attention to detail.”

After completing internal validation, in June 2022, the Optima 160 became operational in ICO Lab’s spaces in Rome, serving the design team. The digital die-cutting system quickly proved to be a valuable ally, accelerating the activities of designing, testing, and validating new packaging and display models, some of which have patent applications submitted.

“Having a compact, professional machine with a camera at our disposal allows us to create and modify prototypes in real-time while sitting with the client,” explains Tempesta. “Optima 160 provides us with autonomy and full control over the product, enabling us to bring to life everything we envision.“

Creativity, technology, and service are the fundamental values that underpin the partnership between ICO and Valiani.

The designers at ICO Lab utilize numerous graphic and structural design tools and applications, working closely with the technical office that uses ArtiosCAD parametric design software to standardize projects in accordance with the company’s coding systems. To meet the needs of their creative process, along with Optima 160, ICO Lab chooses to adopt the Valiani V-Studio software suite, which enables rapid creation and modification of cutting and creasing paths, allowing real-time verification of model efficiency. This choice allows for the design and testing of even complex creases that are difficult to reproduce in parametric CAD.

“From the installation and training phases, Valiani’s technology and the consultancy of their technical and application team perfectly aligned with our philosophy,” concludes Tempesta. Nearly a year after installation, Optima 160 is used daily for prototyping and producing pre-series of dozens of projects, becoming the pulsing heart of ICO Lab. With the assistance of Valiani cutting technology, between 2022 and 2023, the development team has successfully developed four new patented products.